SpiroExpand pressurization

Pressurization is the key to a good system design. Our experience, research and targeted investigations have taught us that most issues within heating and cooling systems are closely related to insufficient pressurization.

Often even straightforward problems are overlooked during design, installation, and maintenance. As a result, the system fluid’s quality is seriously compromised, and a potentially fatal series of events will occur. This dramatically reduces the efficiency of the system and causes premature failure of major system components.

Often it ends up in high operating costs for the plant and considerable expense for the owner and annoying inconveniences for the end-user. Parts need to be replaced, and the system must be cleaned persistently, and time and again, chemicals are applied. All this to achieve a “status quo” for the circulating fluid.

Breaking the cycle of work and costs starts with the pressurization system. A poorly designed, installed and maintained pressurization system can lead to negative pressures around the circuit. Air can be drawn in through automatic air vents, gaskets and micro leaks.

High pressure situations can lead to water being emitted through the safety valves and the subsequent frequent addition of further raw refill water. The introduction of fresh oxygen-rich water depletes any level of corrosion inhibitors that may be present. The onset of corrosion is then inevitable, and the cycle continues:

Corrosion inhibitors do not affect the content of inert gases such as nitrogen and carbon dioxide that are present in large volumes and reduce the operating efficiency of the system.

Each heating or cooling system puts different demands on a pressure control system. Also, operators place additional requirements on the equipment of the pressure control systems, on the possible signal exchange with other parts of the installation or control system and operational reliability.

SpiroExpand covers a full range of solutions, from the most basic setup to the most complicated system. If you can’t find the right plan for you, we’ll be happy to create a customized set up specifically for your problem.

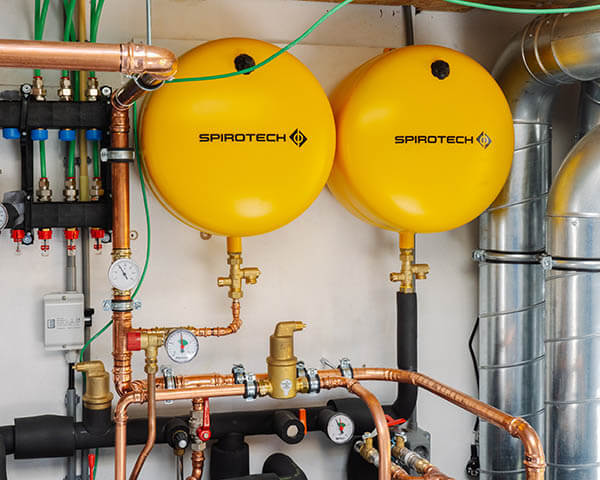

Using a pressurization unit means optimized pressure in your system

and saving space in your boiler room!

These are ‘passive’ pressure management systems. A preset gas pressure in the membrane expansion vessel is used for pressure control. Because membrane expansion vessels do not have a make-up function, we ideally combine this type of pressure control with a vacuum degasser including a make-up function.

The expansion tanks are available in 12 configurations and with volumes between 2 -3000 litre and an operational pressure range from 3.0 – 25 bar.

The PicoControl Kompakt comes in six possible versions (45, 75, 125, 200, 300 or 500 liters). Operating pressure up to 4.0 bar is possible

The SpiroExpand PicoControl Kompakt is equipped with a single pump (1x 100%) and a single valve (1x 100%)

The Multicontrol Kompakt comes in 104 possible versions, with 5 possible container volumes: 75, 125, 200, 300 or 500 liters. Two further containers can be added.

Our Multicontrol Kompakt comes in 5 series and several Partner packages with the following configurations:

More about the MultiControl Kompakt

Download the free BIM files of our MultiControl Kompakt products

The MultiControl Modular comes in 78 versions and 12 vessel volumes: 200 to 10,000 litres. Additional vessels can be added.

Our Multicontrol Modular comes in 5 series with the following configurations:

The MultiControl Cool is available in 6 configurations and 8 versions with volumes of 125 (x2), 200 (x2), 300 (x2) and 500 (2x) liters.

The TopControl Modular is an expansion- and pressure maintenance unit in modular design for combination with the pressureless EG expansion vessels (0,5 bar safety valve).

Our TopControl Modular comes in 5 series with the following configurations:

The SpiroSelect tool is an upgrade of already existing Spirotech tools, combined in one clear online environment. Not only can you now choose an integrated total solution, but you can also select individual solutions in the areas of:

Once you have made your choice, you will receive the selection in a clear file, including technical documentation of the chosen solutions. With that same overview, you can easily and quickly place an order or schedule an appointment for further advice.

When degassing, we recommend following the VDI 4708 and VDI 2035-2 guidelines. In order to achieve the best possible degassing performance in heating and cooling installations, a separate vacuum degasser is necessary in addition to often used deaeration function in pressurization systems’.

The degassing function available with many pressurization systems, will reduce air related issues in closed water circuits, but they cannot guarantee to reach a gas pressure which is lower than the lowest pressure in the system (gas absorption condition). This means a vacuum degasser such as the Spirotech Superior is necessary to meet the VDI guidelines for degassing and deaeration, and for prevention of damage in water heating installations.

In the document below you find 2 connection diagrams with the SpiroExpand MultiControl Kompakt Solo in combination with our vacuum degassers:

A SpiroTrap dirt separator with magnet is also added to the connection diagram to ensure that your system water will be free from dirt and magnetite at any time.